When the technology press talks about the supply chain of the future, it tends to focus on some of the clichés that, while they spark the imagination, tend to veer closer to science fiction than reality.

For logistics and deliveries, there are often mentions of self-driving trucks or drones that can handle last-mile delivery. For depots, distributions, and warehouses, the images are ones of massive aircraft-hangar-sized warehouses without a human soul on site, entirely staffed by robots.

To a certain extent, there are some elements of truth in these visions. Robots do play an increasing part in many warehouses across the world, and while driverless trucks are still safely in testing stages, entire worldwide fleets of all types of transport are carefully tracked and scheduled by advanced technologies.

In practical terms, many challenges face supply chain and logistics managers today that can and are being solved by technology. This series of articles hopes to describe some of the more exciting solutions, and focus on the ones that make practical business sense in 2021. Issues like peaks in demand over national festivals and shopping events, the need to dramatically cut carbon emissions to keep delivery trucks rolling through many of the world’s cities: these are among the many issues that concern supply chain professionals today.

Iterate to improve

Day-to-day operations require changes that create little-and-often improvements. These improvements are then reflected in today’s businesses’ order books and finance software, from those of ocean-going freight operators through bike delivery outfits. In this series of articles, we hope to look at some of the more practical technology-based solutions that make significant differences in several areas of the supply chain and logistics industry.

As an area of technological evolution, our vertical is particularly exciting because of its interconnected nature. Change and improvements in one niche area, like improvements in loading bay metrics, can cause an increased need for improvement in digital connectivity further up and down the chain. As an integrated and organic system, the supply chain, and the elements in it, are an area that is one to watch for anyone with an interest in how technologies are changing business.

For the operations manager in any business anywhere in the supply chain, keeping tabs on the rest of the industry is very necessary: changes to platforms, practices and protocols will indubitably have their effects felt close to home, sooner or later.

In this opening article, we’ll be considering four technical innovators in the industry, vendors whose solutions and practical offerings will make that significant difference to operations. From vehicle fleet management, through picking and warehouse robots, to integration with varying government Customs APIs for import/export, to e-commerce platforms — the intermeshed supply chains and logistics networks that cover the globe are a hotbed of technological innovation.

Here is our opening salvo of four vendors: these are the movers and shakers in this hotbed of technology that is the supply chain of the modern age.

GEEK+

Smart logistics solutions are what Geek+ delivers all over the world today. Right now, its robots and control systems create automations across facility shop floors that drive efficiency, increase the flexibility of the supply chain, and lower costs. The cut in labor costs is significant, and so are reductions in associated overheads caused by mistakes, accidents, and holdups from any source.

Throughout seasonal peaks and troughs of consumer demand, Geek+ platform continues to adapt and provide solutions across the multiple industries, including e-commerce, retail, 3PL, pharmaceutical, and more.

The solution creates technology infrastructure that can pre-emptively adjust the supply chain according to prevailing conditions — that’s down to the information flows that happen in real-time. Day-to-day operations are revolutionized, the business becomes more agile, and its partners benefit too.

Planning and facilitating real-time events can become a fully automated process, with robotized pickers and warehouse robots maximizing capacity on the fly, ensuring human operators work more productively and safely. The Geek+ advantage is one of being able to be proactive rather than reactive to business. It offers modernization of facilities; via the platform, the positive effects spread out across the enterprise through synchronized data and visibility of information silos with benefits beyond the supply chain, allowing the whole business to thrive.

GEOTAB

As a global leader in IoT and connected transportation with over 2.2 million connected vehicles, Geotab provides advanced data insights and fleet management solutions to organizations all over the world, including thousands of logistics companies. Its interoperability with other technology platforms is unrivaled as proven through its vast ecosystem of partners. By implementing Geotab’s technology, many organizations have revolutionized the way they operate through increased fleet efficiency, improved driver safety and reduced maintenance costs.

By monitoring vehicles and driver behavior, companies can unlock a wealth of metrics and performance data that can positively affect every part of the business. Maintenance plans for machinery and vehicles can be honed to help keep investments running for longer, yet performing more optimally, safely, and with greater fuel or power efficiency. Even small details like vehicle movements across depots or yards can yield powerful information that help increase management’s visibility and enable data-driven insights to change operations for the better.

Geotab’s innovations are centered around six pillars: Productivity, Fleet Optimization, Safety, Compliance, Expandability and most recently, Sustainability. These pillars are strategically selected to ensure that the customers’ business remains relevant in a world that is experiencing rapid social, economic, environmental and technological change.

ANCHANTO

Anchanto’s solution was born and bred in Asia, and its multilingual support on the platform (customizable for each user) means it’s the go-to in the APAC for many in the industry. The GUI transitions neatly and clearly from English through Japanese, Mandarin, Bahasa, among others, and provides oversight and management of inventory, order, pricing, and discrete catalogs.

The Anchanto solutions also “speak computer,” integrating via open-standard APIs into other enterprise systems. Companies can tie together logistics, supply chain, and, for instance, internal finance, HR, and CRM systems. Even outside the company’s logistics operations, staff feel the benefits, as previously manual copying & pasting from one system to another gets fully automated.

The Anchanto eCommerce management system (SelluSeller) integrates with 70+ marketplaces common in the region, from niche specialists up to the giants: the likes of Lazada, Flipkart, and Tmall. It handles ordering and fulfillment processes from marketplaces and other websites — including your own e-commerce facilities — and then co-ordinates the supply chain for a fully inclusive service that puts customers’ experiences first.

For warehousing and stock control, the Wareo platform handles stock expiry dates, SKU lists, re-ordering, consignment notes, delivery orders, and so on – the list is long enough that it’s best read on the company’s website!

FLEXPORT

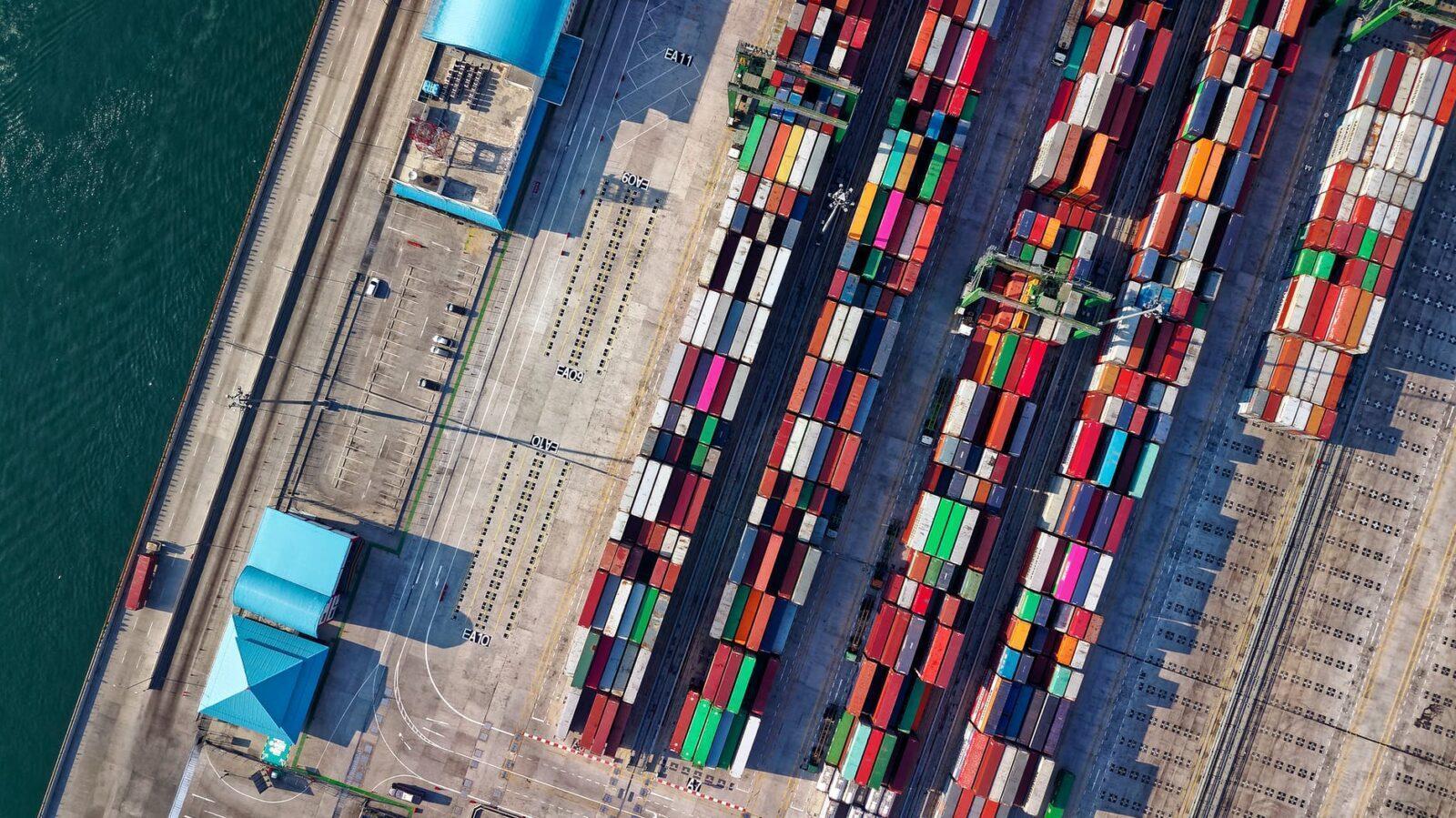

Flexport’s mainstay offering is around all things sea-going and ocean freight forwarding. Full load shipments and multi-port partial loads are tracked, either being carried the company’s own network of vessels or across the common major shipping alliances. That means exceptions (so much part of ocean freight) can be immediately acted on, with operations staff alerted via the highly customizable dashboard that gives a literal worldwide view of real-time activities.

This type of insight plays a critical role in a connected supply chain for companies bound by SLAs or those on a journey to improve metrics and customer experiences. To push this goal more effectively and reduce costs for all its clients, Flexport offers partners container-space-to-requirement matching service. When there’s unused space, it can be offered to other Flexport clients, helping both parties achieve better efficiency and slash consignment costs.

The Flexport solution integrates with truck and air logistics, too, with a highly extensible system that boasts fully ready-to-go APIs for inter-connectivity. There is also a customs and duties facilitation service, which means companies get direct electronic access to filing and rebate systems right across the world. That feature alone saves literally hundreds of hours spent filing paper records with multiple agencies.

Link: https://techwireasia.com/2021/04/freight-carriage-logistics-technology-supply-chain-ocean-air-land-reviews/

Source: https://techwireasia.com

Leave a Reply